Here in the Design Hub we are starting to work on projects that involve into Virtual Reality.

Here in the Design Hub we are starting to work on projects that involve into Virtual Reality.

VR for short. VR is a new and still improving technology that is still in big business today. Everyday it’s improving and new technology is warping its ideas in the system.

VR Headset that is used can help someone see in the eyes of what is happening in the virtual world. Many VR company’s that are popular today are: HTC Vive, Oculus, Windows Mixed Reality.

Basically VR is suppose to help us see in a place we don’t see everyday. Some say it helps people to escape from reality we live today.

Other than games, VR has many purposes that can help people with their day to day lives. VR can be used to help peoples health and give people experiences that they will never have or want to have like go to a unique place or somewhere around the world.In the Design Hub, we are working with 3 projects that are involved in vr.

Other than games, VR has many purposes that can help people with their day to day lives. VR can be used to help peoples health and give people experiences that they will never have or want to have like go to a unique place or somewhere around the world.In the Design Hub, we are working with 3 projects that are involved in vr.

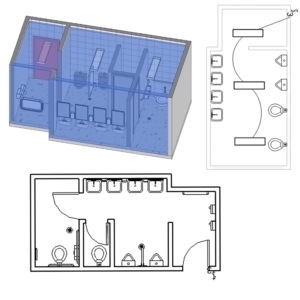

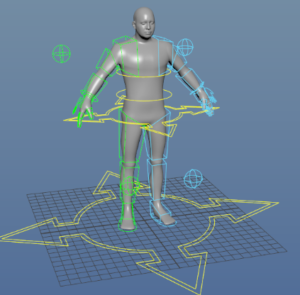

Our first project in VR is called ADABathroom.com. This project is about viewpoints/ experience of a person who really needs it. We currently are measuring bathrooms from places around us that currently have public bathroom. Also we are going to model each and every bathroom that we measure and make. For this project. Then we will convert these models into a VR enviroment that can be used in VR. Then we will test these models and everything out by the experience that we put into the program to replicate what it is like to go to the bathroom by the experience. The on thing that we are still in development but has in mind is to add a log rating system so that we can know the persons rates on the bathrooms and also experience.

Our first project in VR is called ADABathroom.com. This project is about viewpoints/ experience of a person who really needs it. We currently are measuring bathrooms from places around us that currently have public bathroom. Also we are going to model each and every bathroom that we measure and make. For this project. Then we will convert these models into a VR enviroment that can be used in VR. Then we will test these models and everything out by the experience that we put into the program to replicate what it is like to go to the bathroom by the experience. The on thing that we are still in development but has in mind is to add a log rating system so that we can know the persons rates on the bathrooms and also experience.

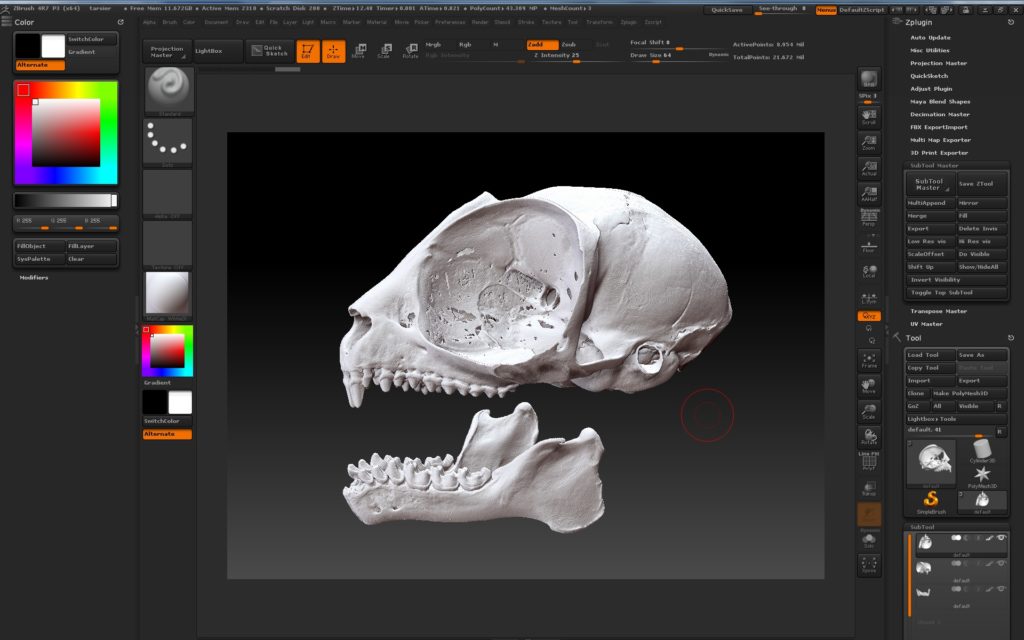

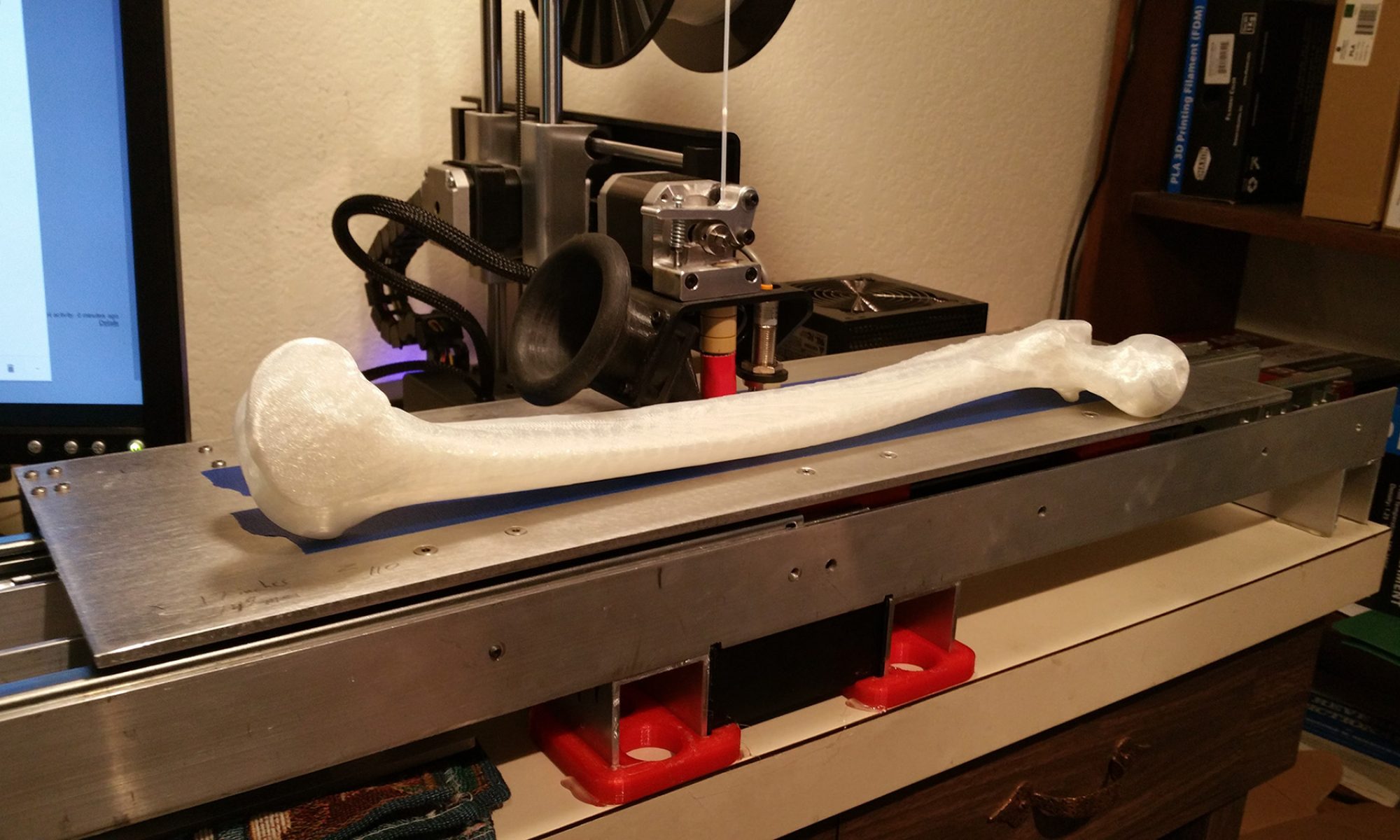

The second VR project is the “ Physics particle Collider “ this project is currently about very slow motion of high energy physics of particles and see how they can interact with one another. There are currently no educational vr models out in the market. So we have to create each model ourselves.

The third and final project is the Stem building project. Currently we only have the building for the VR. But we need to populate the building with items and people. But also we have to add other buildings surrounding it to replicate the ARC campus. The reason for that is to help indicate what it would feel like to have it in already built and surrounding with ARC buildings so we know how and what it would feel and look like in the college.

The third and final project is the Stem building project. Currently we only have the building for the VR. But we need to populate the building with items and people. But also we have to add other buildings surrounding it to replicate the ARC campus. The reason for that is to help indicate what it would feel like to have it in already built and surrounding with ARC buildings so we know how and what it would feel and look like in the college.

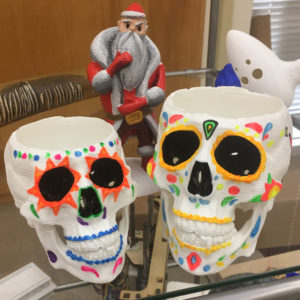

Just like a previous blog post about Holiday Wars; Daniel and his team is still working on finishing up this project and getting the game ready to be able to play.

Just like a previous blog post about Holiday Wars; Daniel and his team is still working on finishing up this project and getting the game ready to be able to play.  The fidget spinner made from a transmission gear box that can be reduced 1 to 10. Which means the ratio of the numbers of turns that the fidget spinner moves.

The fidget spinner made from a transmission gear box that can be reduced 1 to 10. Which means the ratio of the numbers of turns that the fidget spinner moves. Modeled and designed using the program, AutoCad. Its also Ivan’s deliverable from Randy.

Modeled and designed using the program, AutoCad. Its also Ivan’s deliverable from Randy.