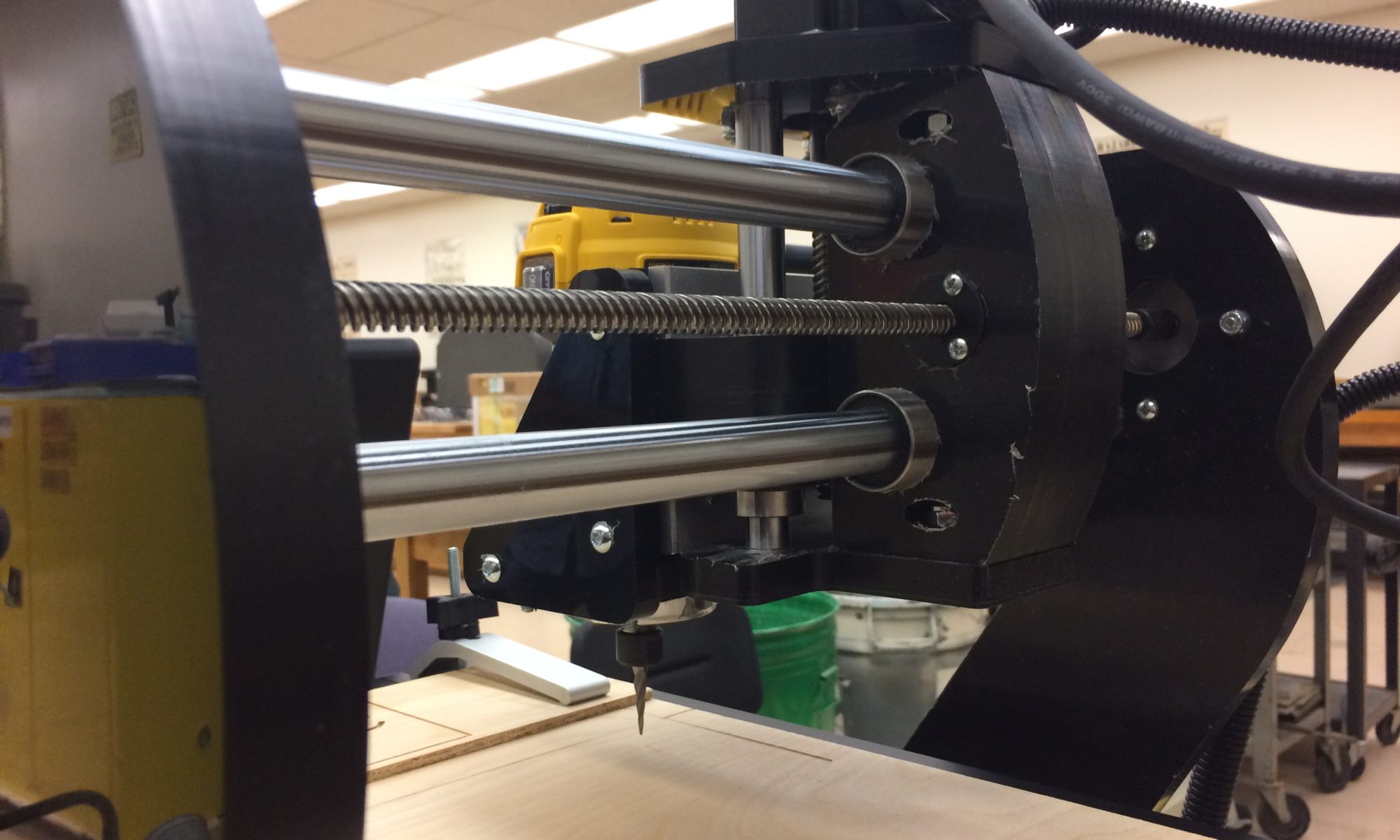

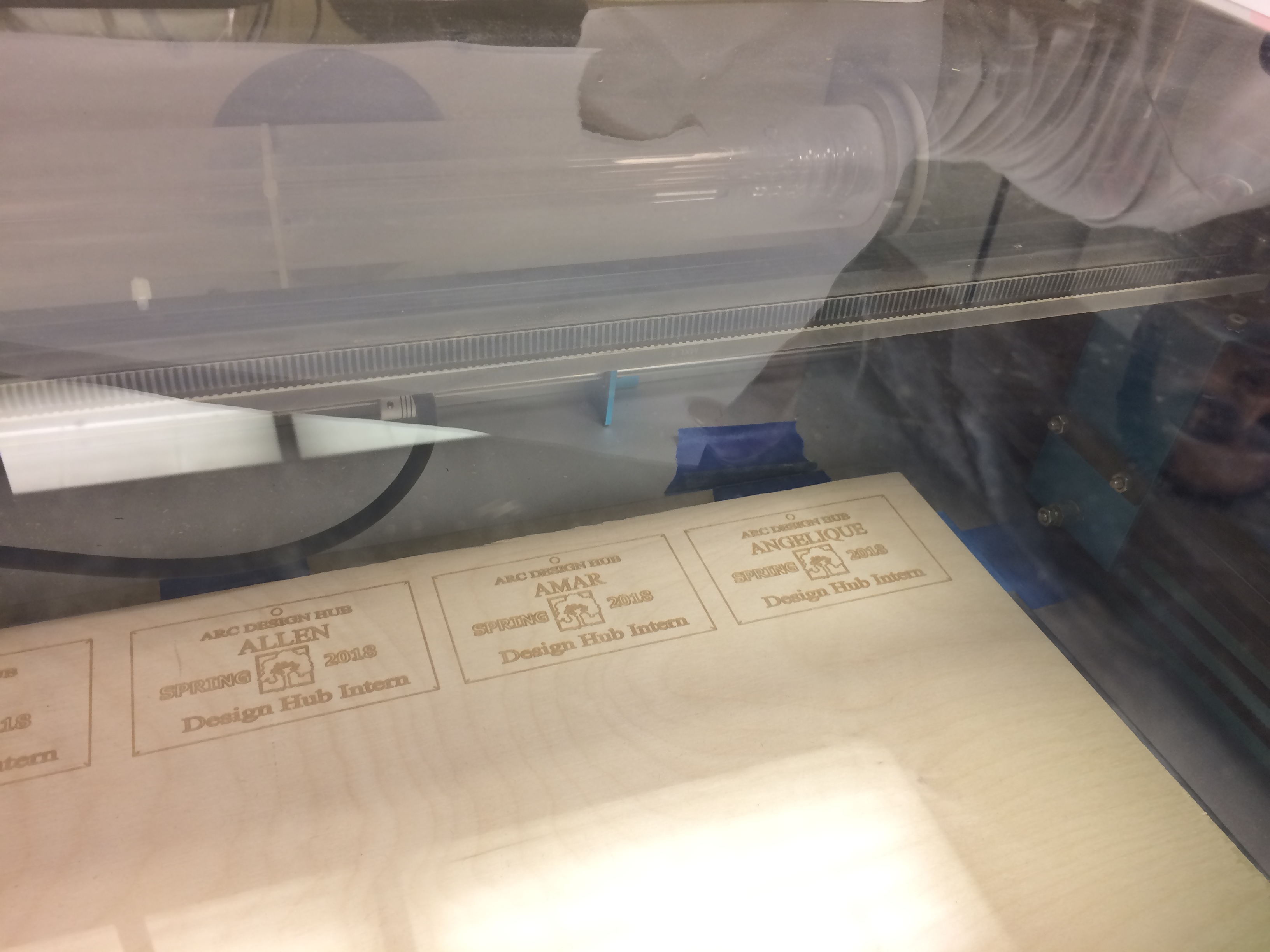

The Design Hub of American River College conducted one of the first projects using the Laser Engraver. Shailza, one of the laser engraver interns working on this project, demonstrated how it produces the gentle, artistic shades of black and white on the sturdy wooden boards. Plywood is used as the canvas, and the laser carves in its drawings. The Laser Engraver obeys the commands sent by the software on the computer to create whatever artwork the intern orders it to. For this particular project, the deliverables are name tags made of wood for all the interns who are working for the Design Hub.

This project of engraved name tags gives all the interns a sense of community, since we are always collaborating and working together to contribute each unique skill set to the various projects. The original idea for this project was right at the beginning of this spring semester because it gives a feeling unity and family to the new incoming interns just now joining the team. The engraved name tags were completed a couple of weeks ago, and can be viewed in the Design Hub lab. Even though the actual project for the engraved name tags is complete, the Laser Engraver will be frequently used during the full course of this semester.

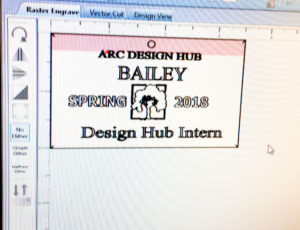

The Full Spectrum Laser Retina Engrave 3D software orders the laser to cut out the name tags. The shaded pink section we can see in the photo to the left is the area that the laser already engraved, and the white areas are what is left to be carved until the project is finished.

Shailza, a hard-working intern trained in the art of laser engraving, showed a one-on-one demonstration of the laser engraver in action! First, you open up the file in the special software, Full Spectrum Laser Retina Engrave 3D. She showed the computer settings required for the engraver.

FUN FACTS:

- Whatever image that the intern wants to print must be in xps format

- The raster power CANNOT be at 100%- we have found it most effective to be set at 65-70% for the best wooden artwork.

- The raster speed is set between 45-50%, and the vector layers power is set at 70%. The IP address should show up on the laser screen.

- And “Slow jog” isn’t just something a student does when they’re late to class on a Monday morning after sleeping through their alarm, it’s also the setting on the control panel to give the intern more control over the laser so it doesn’t go flying off in a frenzy.

Once the settings are properly set, the wood is positioned to be carved into, and watch the time at the bottom of the screen allows the students a time frame for when their project should be completed. The average time is 7-8 minutes- like for the name tag project- but it depends on the size of the wood/project.

The next project also on the Laser Engraver leads us to meet Jacob Olson, who brings ideas to life through the art of 3D printing and laser engraving. He is trained in laser engraving and is a solid modeler for the Design Hub. He also tutors design technology programs such as Autocad, Revit, Sketchup.

Jacob takes family photos, and creates images printed onto wood through the scientific world of computers, cyberspace, and LASER TECHNOLOGY (cue the “Twilight Zone” theme song).

Jacob is providing this project with his own family photos of his great grandparents, inspired by his father’s idea, and giving them as a present to his grandpa. The end product will be a collage of family photos laser engraved in the plywood. Jacob showed us around the laser engraver to get a feel for it and showed me exactly how the machine works: the water filter from the bucket pumps up water and keeps the laser tube cool while the exhaust fan pulls out smoke and filters out the exhaust to prevent turning the interns’ hard work into a barbecue. There’s a cycle of water that goes from being pumped from the bucket, to the laser tube and back to the bucket in a little circle of life.

The artists of the Design Hub have an ongoing task of creating new ideas to contribute to being engraved into wood using the Laser Engraver. There has been extensive training to prepare the interns on how it’s used, including training sessions they attended, as well as sample tests before running the actual name tag project.