Design Hub student Shayn found inspiration in his teacher’s words: “You just gotta do it!” Quoted from none other than the welding professor here at ARC, Chris Messier. “When he’s not teaching his students all he knows, he’s creating vacuum chambers with gloved hands and sheet metal. He is pictured giving an example of the TIG- or GTAW- welding process, something that is proven to be a pretty tricky task. Shayn tells us that he is taking his fabrication and blueprints reading class in the welding department at ARC. As Shayn explains this process, he gives us a piece of welding slang: “stacking dimes”, which is the process of getting the weld to look like dimes that have been melted on top of each other. “It’s actually the sign of a job well done,” Says Shayn. Seeing students inspired by their professors is always a great thing to see. Teachers leave not only an impression on the students, but on the campus community of makers, including those here at the Design Hub. Thank you Chris Messier for all that you do, and thanks to Shayn for sharing! More of Professor Messier’s work can be found on his instagram page: @mez_welds

Design Hub student Shayn found inspiration in his teacher’s words: “You just gotta do it!” Quoted from none other than the welding professor here at ARC, Chris Messier. “When he’s not teaching his students all he knows, he’s creating vacuum chambers with gloved hands and sheet metal. He is pictured giving an example of the TIG- or GTAW- welding process, something that is proven to be a pretty tricky task. Shayn tells us that he is taking his fabrication and blueprints reading class in the welding department at ARC. As Shayn explains this process, he gives us a piece of welding slang: “stacking dimes”, which is the process of getting the weld to look like dimes that have been melted on top of each other. “It’s actually the sign of a job well done,” Says Shayn. Seeing students inspired by their professors is always a great thing to see. Teachers leave not only an impression on the students, but on the campus community of makers, including those here at the Design Hub. Thank you Chris Messier for all that you do, and thanks to Shayn for sharing! More of Professor Messier’s work can be found on his instagram page: @mez_welds

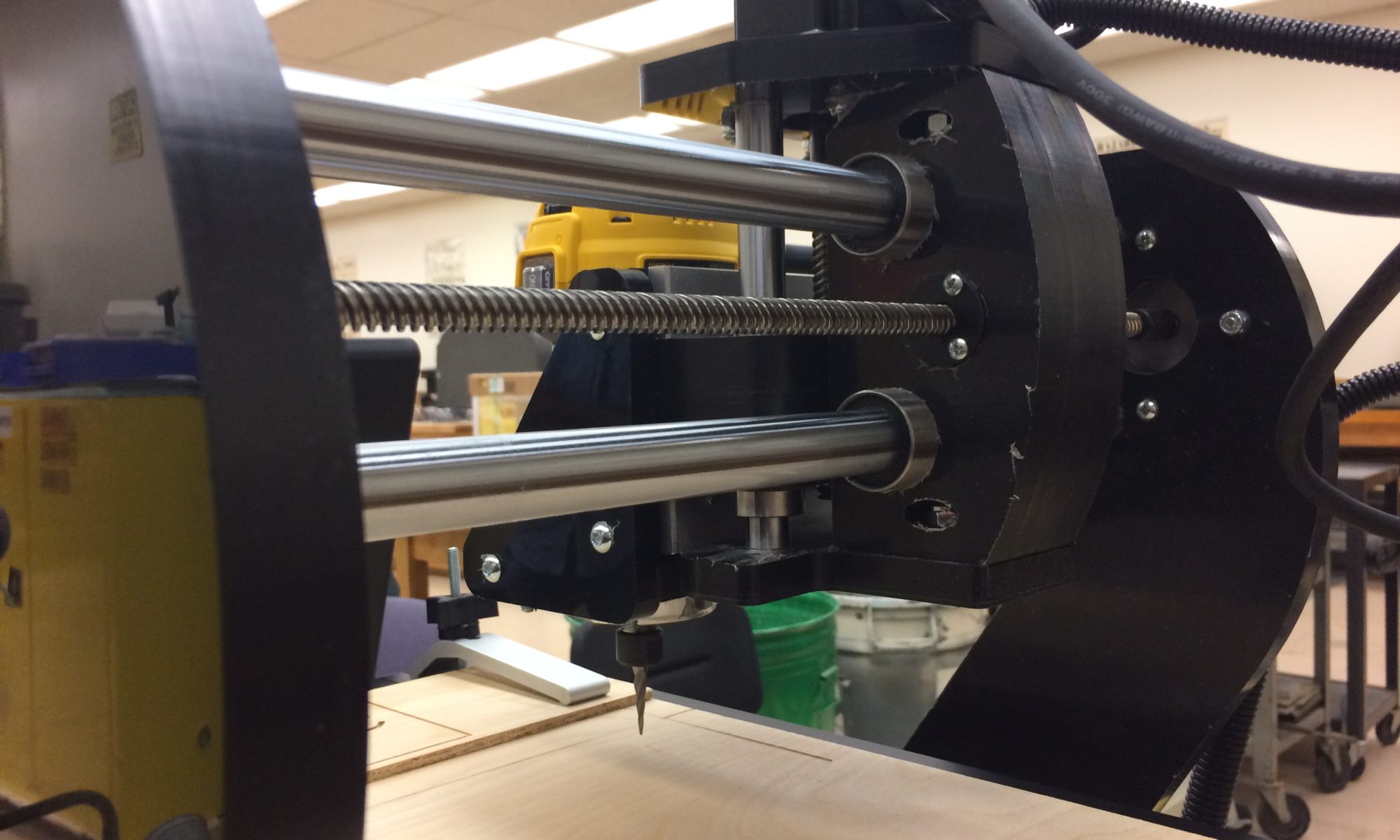

CNC Router

The CNC Router interns gave a tour around their machine in the back room of the Design Lab Room 311. The router was being tested first to make sure that it works properly before executing the projects. It is being tested on plywood.

This particular project on the CNC Router is the letters, “ARC” being drilled into the wood as a test before other, more complex images are carved into the wood. After the initial testing takes place with just the letters, “ARC,” then the router interns will move on to further advanced projects such as carving out detailed photographs.

To do this, first the intern must use the software, V Curve, to upload, design, and save the file onto the computer. Then load the image to the CNC control panel which will command it to cut into the wood. Home on the CNC Router control panel tells it where to start cutting. The interns can actually set how far deep they want to cut into the wood also at the home button on the control panel. Randy ordered the CNC Router interns to test out this machine to prepare it for further use later on for more projects. There is an ongoing series of projects using the CNC Router throughout the semester. It can be viewed in the Design Lab, where some of the beautiful woodwork is displayed. This particular project of engraving a family photo from an image on the computer screen to a piece of plywood is especially meaningful for people who want pictures to last longer than they would on paper. It’s a special way of remembering those we cherish, because one can have the gorgeous frame with them for life.

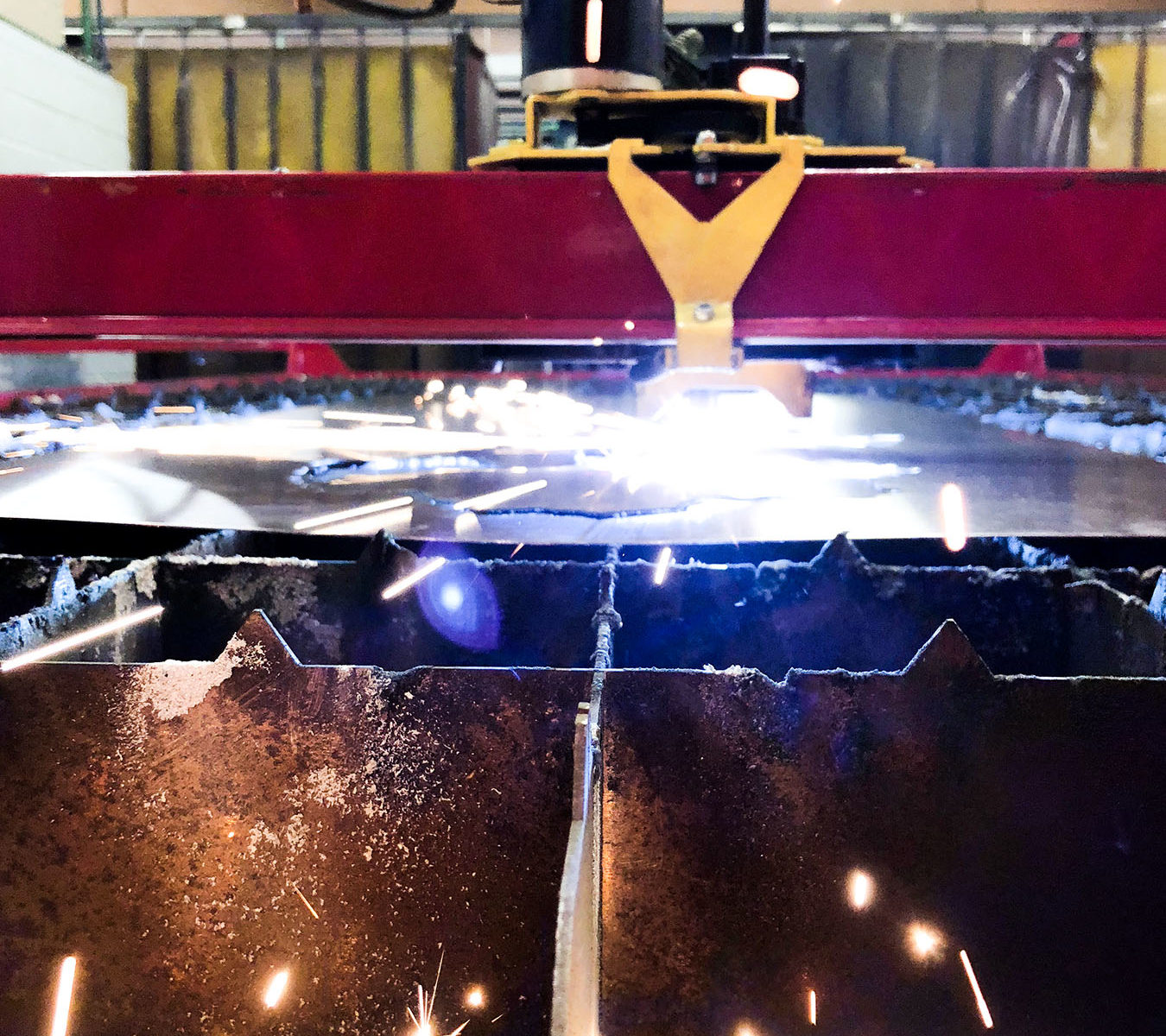

Sparks are Flying at ARC’s Design Hub

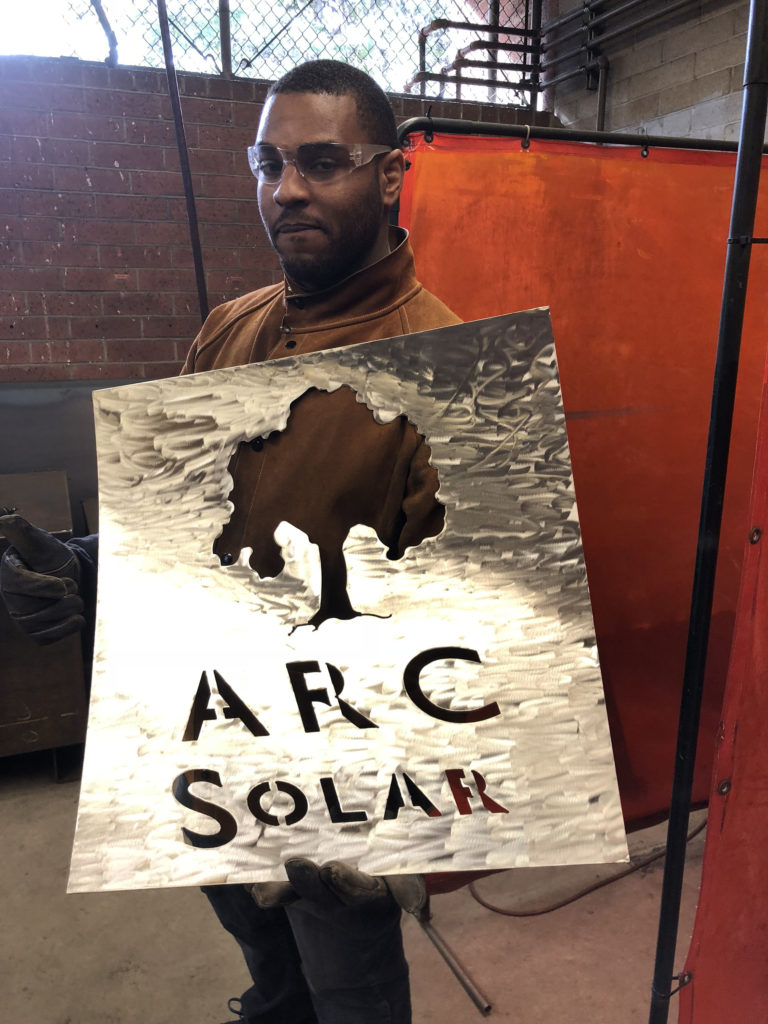

Thanks to the welding department, Allen Peterson III, one of our amazing Mechanical Engineer students with a background in welding, has been working on the Sign Production Project.

Using the Plasma CNC Cutter, he has been creating signs on Stainless steel sheet metal for use around campus to allow students to better recognize the locations/identify different departments. How the signs will be displayed is still to be determined, but they will soon be seen on the doors, walls or displays around campus very soon.

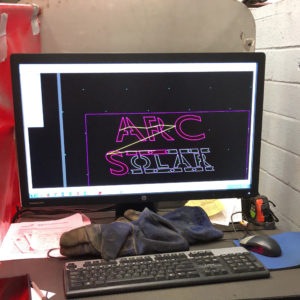

We took a closer look into the process of making these signs. Needless to say, there are a lot of steps and close attention to detail that is involved. First, our intern Allen has to align the Plasma Cutter with the sheet of metal through coordinates on the computer. After aligning the Cutter, a font must be picked and placed within the coordinates to determine where they will be cut on the metal.

We took a closer look into the process of making these signs. Needless to say, there are a lot of steps and close attention to detail that is involved. First, our intern Allen has to align the Plasma Cutter with the sheet of metal through coordinates on the computer. After aligning the Cutter, a font must be picked and placed within the coordinates to determine where they will be cut on the metal.

Then comes the fun part. As the metal is being cut, a spectacle of sparks light up the workspace. It is something hypnotic to behold, as the image is slowly made visible through the spark showers of the plasma cutter.

After the metal is cut, Allen used a grinder to create the nice finish that we see on the sign. The new, eye-catching difference in the texture of the metal is something worth marveling at.

The departments that have had signs made for them include our Physics, Engineering, Solar, Early Child Development, Chemistry, Biology, and Design Tech departments. The goal is to have easily recognizable campus departments, while at the same time beautifying our school. At the Design Hub, we are eager to help make our campus a better place. We utilize our student’s talents so they can be the force that helps benefit our campus life, and we can be the force that helps them gain the experience using this incredible machinery to eventually enter the workforce.

Exploring Language Through Technology and Art at the Design Hub

American River College’s Spanish 361 class, led by Professor Currea, is about learning and applying the student’s knowledge of Spanish through conversation. Rather than just studying and learning phrases, Professor Currea challenges her students to learn a new skill all while speaking Spanish. The class attended the Kaneko art gallery- American River College’s art gallery on campus that houses all of our student artwork. They observed and conversed in Spanish about their thoughts and impressions of the artist’s work. Afterwards, each student was asked to choose a word that best described what they felt or took away from the experience. This past week, the new skill that the class was taught in Spanish was how to prepare their chosen Spanish word from the art experience for laser etching. The students were each asked to pick a word that represented all of the emotions, experiences, and thoughts about the artist’s work, and how that could be generated and laser etched by the Design Hub. This project then given back to the artist, bringing the experience full circle as the students show their appreciation through their application of the Spanish language.

On Thursday, February 22nd, the class was brought into the Design Hub, where Sean gave a tour of where lab and a demonstration of how the 3D printer works so the students could see all that the Design Hub has to offer.

During this visit, we had the opportunity to conduct some quick interviews with some of these students.

One of them was Peter Brixie, their word: Hermosa. Peter has greatly enjoyed Professor Correia’s class. The most helpful part about having to constantly converse with others in Spanish is that it helps make speaking in Spanish second nature. For Peter, thinking about the translation between English and Spanish all in his head was the most challenging task for him. Having the class focus more on conversing has been greatly beneficial and fun for Peter learning Spanish. His word that he chose to add to the word cloud was “hermosa”, meaning “beautiful”.

Another student, Theresa Pavale had the word “la vida”. Theresa told us she is studying to be a nurse practitioner in the trauma center, and was really impressed when Randy showed how the Design Hub is able to 3D print bones and anatomical models for her department. She was also impressed by the amount of resources that the Design Hub would be able to provide students like her with. The word that she chose was “la vida”, meaning “life”. She was very taken with the painting titled, “Water of Life” and the meaning of the painting: that if there is life, there will be water and how you cannot have one without the other.

It was great to hear from these students and to get the opportunity to introduce them to our Design Hub community. As well as hearing how they applied the Spanish language to art, it serves as an example that being able to use different ways to communicate about things can be a force to broaden our understanding and perspective on the world.

We appreciate Professor Currea and the wonderful Spanish 361 class for visiting, and allowing us to share our beloved corner of campus.

Art Meets Science Here at American River College’s Design Hub

The Design Hub here at American River College is a strong proponent of multidisciplinary collaboration. At the Hub, team-building across all planes is valued and celebrated. It is a place where the arts and sciences come to eclipse, and the outcome is something truly spectacular.

Here, we meet Erika Gonzalez to learn more about about her job as an artist for the Design Hub. Her current project: to paint the cell membrane models for the Science Department. These little cell membranes required the help of Erika’s excellent painting skills, 3D printing, the Science Department, and 3D modelers to create the cell membrane structure. Erika is the lucky intern who was chosen to complete this project. ARC’s Science Department ordered the models of the cell membranes from Randy Schuster, the head supervisor of all the interns that make up the Design Hub. He has made sure to connect with nearly every department on campus, and runs the Design Hub in such a way that allows ARC’s campus to benefit from all of the hard work, talent, and innovation that comes out of the Hub.

The diagram of the model was sent from the Science Department to the 3D modeling interns at the Design Hub. They then transformed the structure into a file format that the 3D printers could handle. From there, the files were transformed into printable structures, and were given to Erika to paint and bring to life. She had to paint each minute crevice in the same way as the 3D printed grain, paying a lot of attention to detail. She is painting the cell membranes with acrylic paint, then sealing it with Mod Podge to prevent the acrylic paint from chipping. This project will be housed at the Design Hub lab room 311, and it will be on display in the Science classrooms. It will also be used as a class reference for the Science Department. The Design Hub is very proud of the collaborative efforts of our many talented 3D printing modelers, our artist intern Erika, as well as the Science Department. When art marries science and design, the possibilities are truly endless!