A beautiful masterpiece!

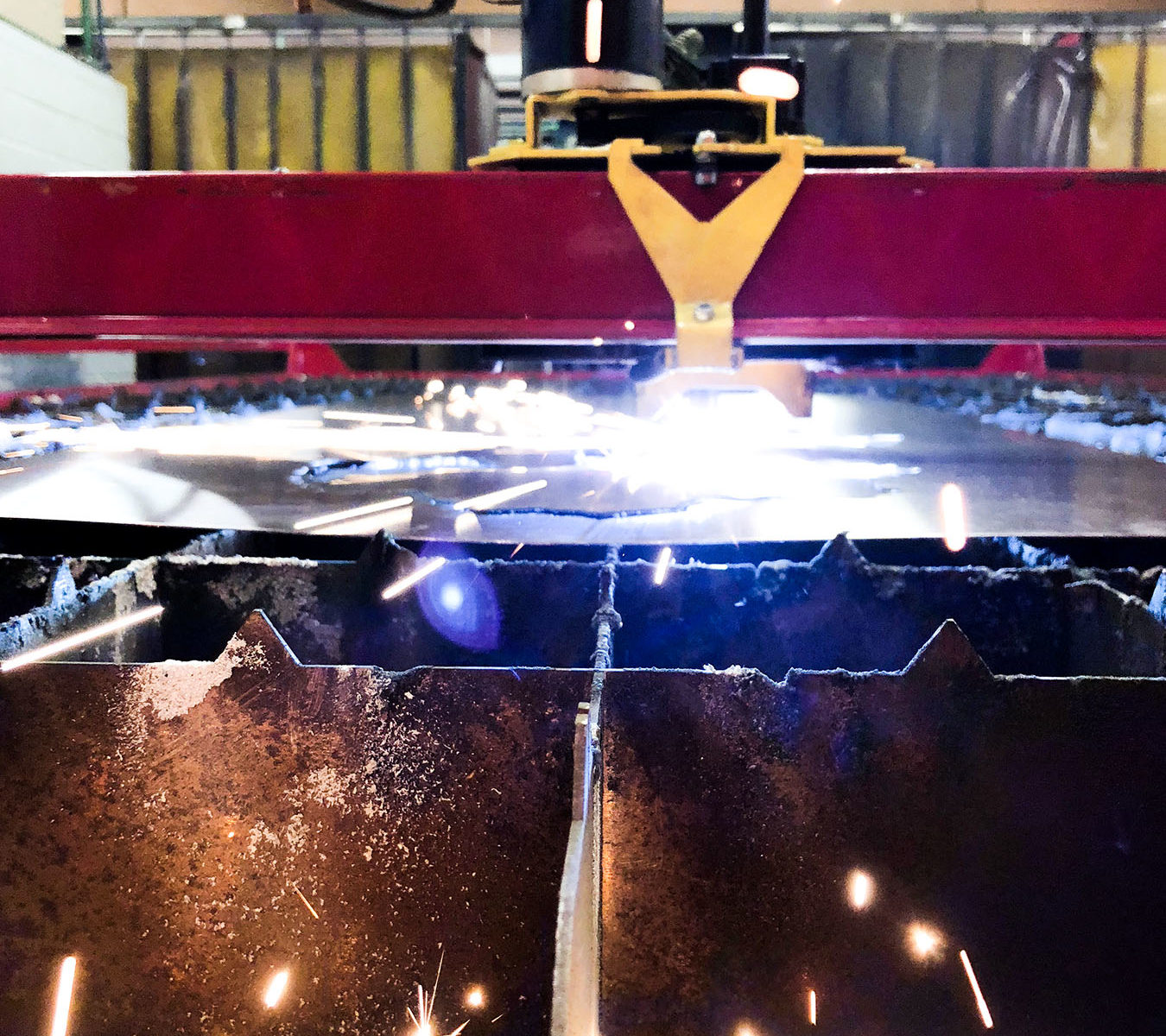

Allen Peterson and U.N.I.T.E. was involve with a certain project. In this particular project, He used the plasma cutter to cut out aluminum shapes to create a unique design made by the Landscape Architecture Class. The Aluminum shapes is a “mock up” of a plan that the Landscape Architecture Class constructed for a future project.

The little metal sculpture will someday be built like posts or fenced around a building. The square bottom part will acted as a fence and the top parts with magnificent design, like birds and trees. It will act to give it a unique design to help make the area it was located in very attractive!

This beautiful piece was created approx. 3 hours in only one day!

Design Hub’s participation to this project supports the architecture students creativity. The Architecture class needed a miniature variant of the final project to be able to test out the original idea. In a way, They can predict upcoming obstacles or arrangements that may arise in the future.

From a photograph, Allen was able to set it up on a plasma cutter.

Future developments from this project is a metal trophy of a break-dancer for the winner of the Break Dancer Competition for U.N.I.T.E.

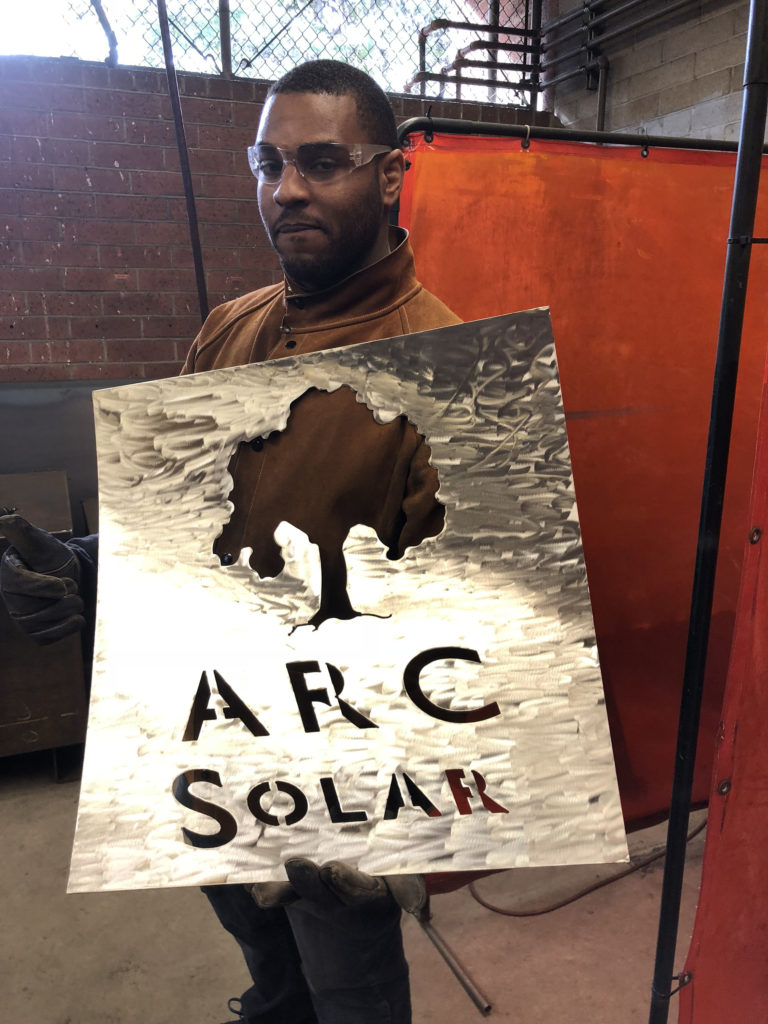

Further development from American River College tree logo on April 24 that Allen made.

This project has traveled to a few locations-

Design Hub to the welding location , then back to Design Hub and then off to be displayed at the Architecture Class.

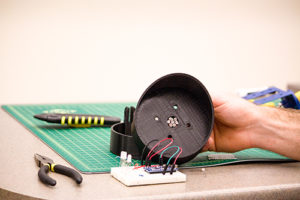

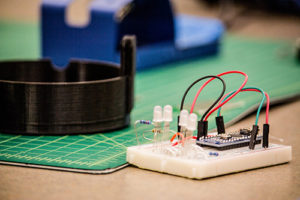

Design Hub student Shayn found inspiration in his teacher’s words: “You just gotta do it!” Quoted from none other than the welding professor here at ARC, Chris Messier. “When he’s not teaching his students all he knows, he’s creating vacuum chambers with gloved hands and sheet metal. He is pictured giving an example of the TIG- or GTAW- welding process, something that is proven to be a pretty tricky task. Shayn tells us that he is taking his fabrication and blueprints reading class in the welding department at ARC. As Shayn explains this process, he gives us a piece of welding slang: “stacking dimes”, which is the process of getting the weld to look like dimes that have been melted on top of each other. “It’s actually the sign of a job well done,” Says Shayn. Seeing students inspired by their professors is always a great thing to see. Teachers leave not only an impression on the students, but on the campus community of makers, including those here at the Design Hub. Thank you Chris Messier for all that you do, and thanks to Shayn for sharing! More of Professor Messier’s work can be found on his instagram page: @mez_welds

Design Hub student Shayn found inspiration in his teacher’s words: “You just gotta do it!” Quoted from none other than the welding professor here at ARC, Chris Messier. “When he’s not teaching his students all he knows, he’s creating vacuum chambers with gloved hands and sheet metal. He is pictured giving an example of the TIG- or GTAW- welding process, something that is proven to be a pretty tricky task. Shayn tells us that he is taking his fabrication and blueprints reading class in the welding department at ARC. As Shayn explains this process, he gives us a piece of welding slang: “stacking dimes”, which is the process of getting the weld to look like dimes that have been melted on top of each other. “It’s actually the sign of a job well done,” Says Shayn. Seeing students inspired by their professors is always a great thing to see. Teachers leave not only an impression on the students, but on the campus community of makers, including those here at the Design Hub. Thank you Chris Messier for all that you do, and thanks to Shayn for sharing! More of Professor Messier’s work can be found on his instagram page: @mez_welds

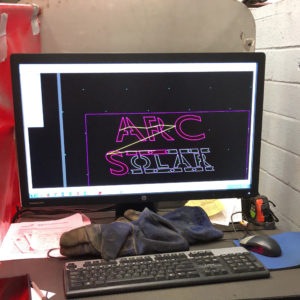

We took a closer look into the process of making these signs. Needless to say, there are a lot of steps and close attention to detail that is involved. First, our intern Allen has to align the Plasma Cutter with the sheet of metal through coordinates on the computer. After aligning the Cutter, a font must be picked and placed within the coordinates to determine where they will be cut on the metal.

We took a closer look into the process of making these signs. Needless to say, there are a lot of steps and close attention to detail that is involved. First, our intern Allen has to align the Plasma Cutter with the sheet of metal through coordinates on the computer. After aligning the Cutter, a font must be picked and placed within the coordinates to determine where they will be cut on the metal.