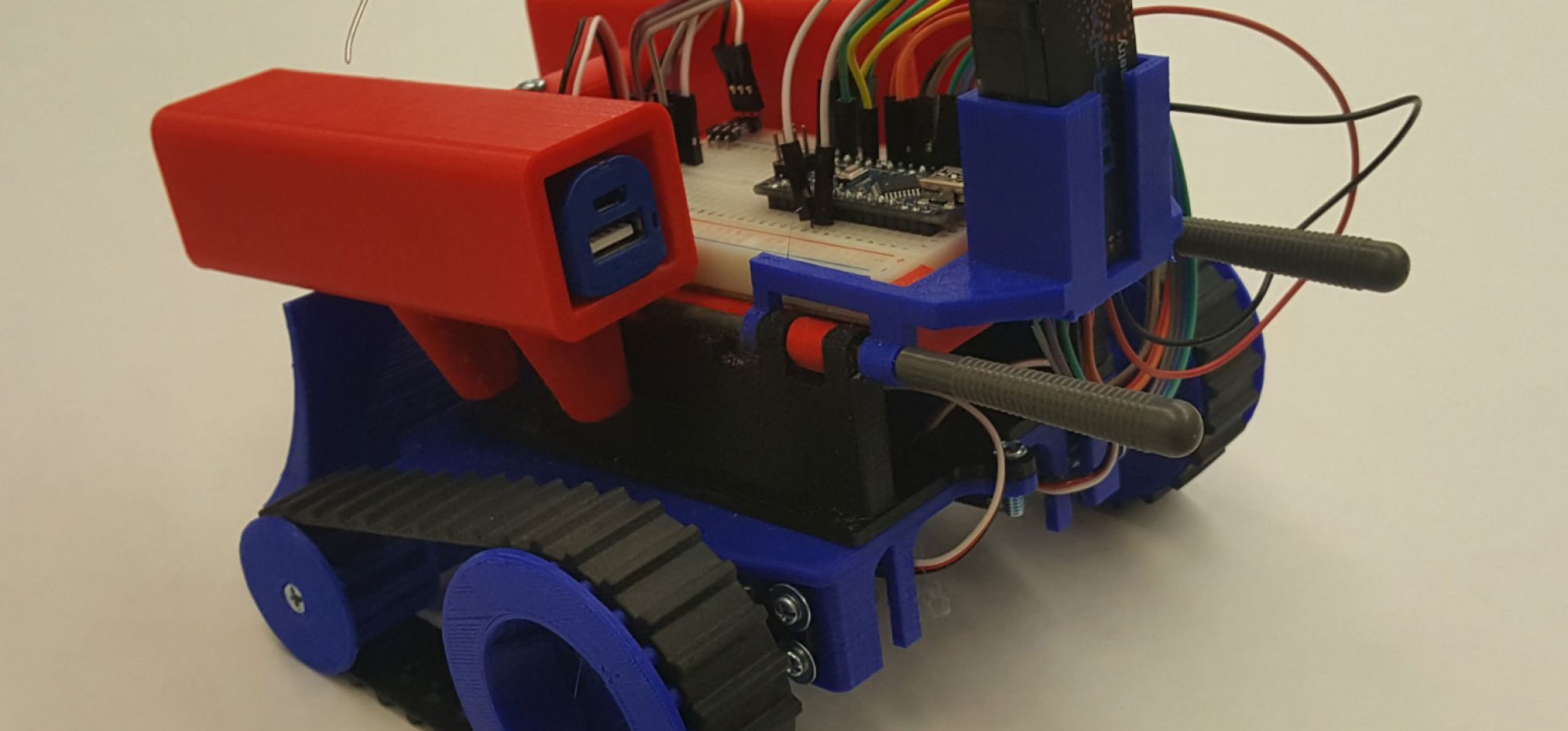

Ivan, intern from the Design Hub, has made the next gen fidget spinner.

The fidget spinner made from a transmission gear box that can be reduced 1 to 10. Which means the ratio of the numbers of turns that the fidget spinner moves.

The fidget spinner made from a transmission gear box that can be reduced 1 to 10. Which means the ratio of the numbers of turns that the fidget spinner moves.

This individual project was originally intended on being model for a transmission gear box. But not for heavy industrial motors such as those found in cars or any other kind of automobiles. The actual one will be for smaller, motors that would accept it better. Since the model was finished, Its original use of the project as a model had been completed.

So now its new purpose is a handy dandy fidget spinner! Discovered by ARC Design Hub Head Randy Schuster.

Ivan’s current plan is to build 10 fidget spinners out of this little plastic model. The final product of this model will move and twist at a super slow speed, Its a creative way to put this idea together.

Modeled and designed using the program, AutoCad. Its also Ivan’s deliverable from Randy.

Modeled and designed using the program, AutoCad. Its also Ivan’s deliverable from Randy.

The stack of ten fidget spinners will not be sold as a whole. However, each individual fidget spinner will be going on sale soon in the ARC Bookstore.

The price of the fidget spinner is going to be approximate $4 per spinner.

Since the model is made out of plastic its not going to be used as real motors.

The real one is made from a sturdy material such as metal and steel. It took Ivan 3 days, Approx. 6 hours to design the model himself. It took one week of 3D printing to make it come to life!

Design Hub student Shayn found inspiration in his teacher’s words: “You just gotta do it!” Quoted from none other than the welding professor here at ARC, Chris Messier. “When he’s not teaching his students all he knows, he’s creating vacuum chambers with gloved hands and sheet metal. He is pictured giving an example of the TIG- or GTAW- welding process, something that is proven to be a pretty tricky task. Shayn tells us that he is taking his fabrication and blueprints reading class in the welding department at ARC. As Shayn explains this process, he gives us a piece of welding slang: “stacking dimes”, which is the process of getting the weld to look like dimes that have been melted on top of each other. “It’s actually the sign of a job well done,” Says Shayn. Seeing students inspired by their professors is always a great thing to see. Teachers leave not only an impression on the students, but on the campus community of makers, including those here at the Design Hub. Thank you Chris Messier for all that you do, and thanks to Shayn for sharing! More of Professor Messier’s work can be found on his instagram page: @mez_welds

Design Hub student Shayn found inspiration in his teacher’s words: “You just gotta do it!” Quoted from none other than the welding professor here at ARC, Chris Messier. “When he’s not teaching his students all he knows, he’s creating vacuum chambers with gloved hands and sheet metal. He is pictured giving an example of the TIG- or GTAW- welding process, something that is proven to be a pretty tricky task. Shayn tells us that he is taking his fabrication and blueprints reading class in the welding department at ARC. As Shayn explains this process, he gives us a piece of welding slang: “stacking dimes”, which is the process of getting the weld to look like dimes that have been melted on top of each other. “It’s actually the sign of a job well done,” Says Shayn. Seeing students inspired by their professors is always a great thing to see. Teachers leave not only an impression on the students, but on the campus community of makers, including those here at the Design Hub. Thank you Chris Messier for all that you do, and thanks to Shayn for sharing! More of Professor Messier’s work can be found on his instagram page: @mez_welds