Here we meet our Design Hub interns, Dave and Melissa, to explore their new project titled, “Constant Monitor Backflow.” Dave and Melissa, as well as our Design Hub team lead Randy are involved in the fulfillment of the project. Randy was asked by a former co-worker, Bernie Clark, who does field research for Watts, Aims, Fab Co, and most of the back flow companies.

This project has to do with our water systems, where the industry today is faced with a challenge. From time to time, our potable water sources can come in contact with contaminants, and the problem our population is faced with is detecting when exactly this happens. Currently, there are annual tests that detect problems, but this is a cause of concern because they are not only costly, but we have to wait a year to see a problem. By the time any problems are detected from these annual tests, damage could already be done, and even more time and money would have to be spent in order to fix these problems.

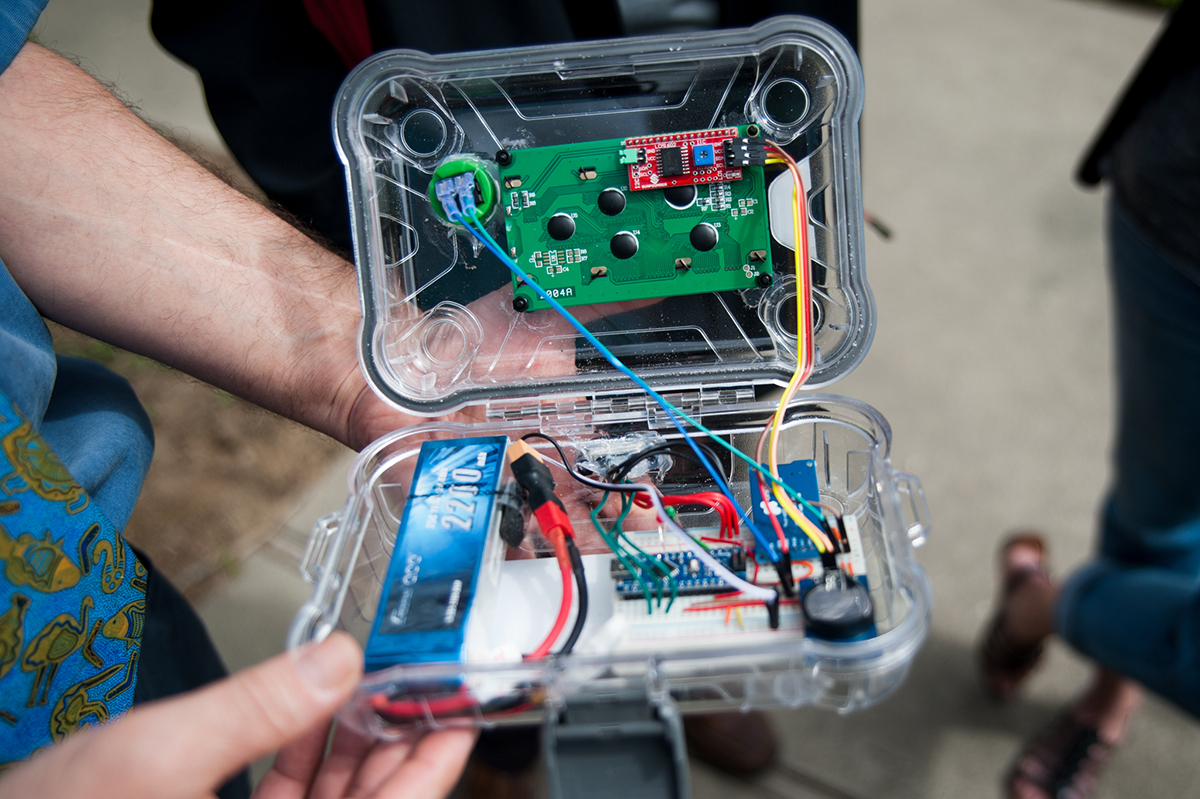

Of course, our interns saw a challenge, and came up with a solution: blackflow prevention monitors! What the Constant Monitor Backflow project is setting out to do is to eliminate this scenario by implementing a new system where we monitor the backflow prevention to detect problems before they happen. These backflow monitors detect the contamination of the pure water with the sewer lines quickly, providing data that is easily accessed. Now it can be constantly monitored, which will help to detect problems sooner so that they can be fixed in a timely manner. This will increase productivity, and they do not need to turn off the water for the constant monitoring, unlike the annual tests, where the water has to be shut off.

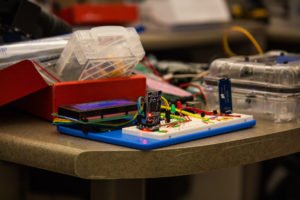

Without the hard work of our dedicated interns, this project would not have been made possible. It began about two years ago, and as this project has unfolded, Design Hub intern Dave has been responsible for the many hours behind the creation of these backflow prevention monitors. He tells us that everything that lies in place now within the confines of these little boxes, all started in his head. He coded the device in our Design Hub lab, making sure it would properly collect and display data, and hand-crafted the circuitboard, complete with all of the wiring and placement within the device.

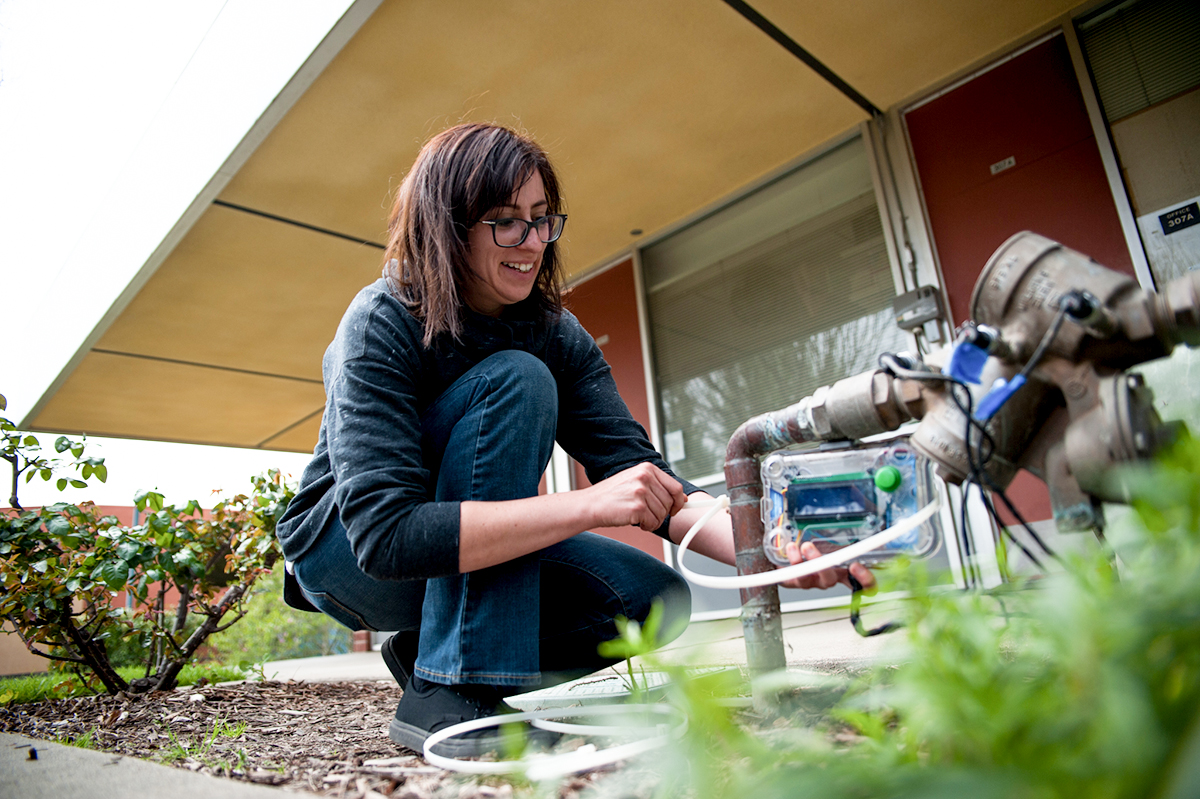

Alongside Dave we have intern Melissa, who has been learning the ropes of this project and training as she assists in implementing these monitors. She will one day have the torch passed on to her as this project continues to evolve. Our interns predict that this project won’t end anytime soon, as it is constantly growing and they continue to brainstorm new ways to improve its productivity.

We are hoping that by the end of the summer, there will be monitors set up all over the entire campus. Currently, we have one monitor backflow. By the end of the summer, the interns’ goal is to have one monitor per backflow all over the campus. By increasing the number of monitors, this will help increase the prevention of problems.

In the long run, we are seeking to collect enough data to prove that these devices, though small, are actually quite mighty. As our interns work to fine-tune these monitors, our hope is to have the opportunity to impact an important industry in a vastly positive way. Few things are as important as safe drinking water, and we are setting out to keep it safe in a clean, efficient, and budget-friendly way.